Key features

- Configurable thermoformer

- Machine Length: 40' frame

- Rigid pack, top lid or MAP process

- Film Thickness : Up to 50 mil

- Film Width : Two machine frame up to 16,61"

- Advance Step: Up to 18"

Forming & Sealing Process

- Forming : Independant station / Separated preheating and froming station / forming station with forming mechanical assistance / without cooling process

- Sealing : Independant station without cooling process

- Transversal : Rigid crush cutting station / Punching cutting station / Shape cutting station / Progressive shape cutting station

- Longitudinal : Motorized shaft with QCO echangeable cutting shaft / Shared knife cutting shaft

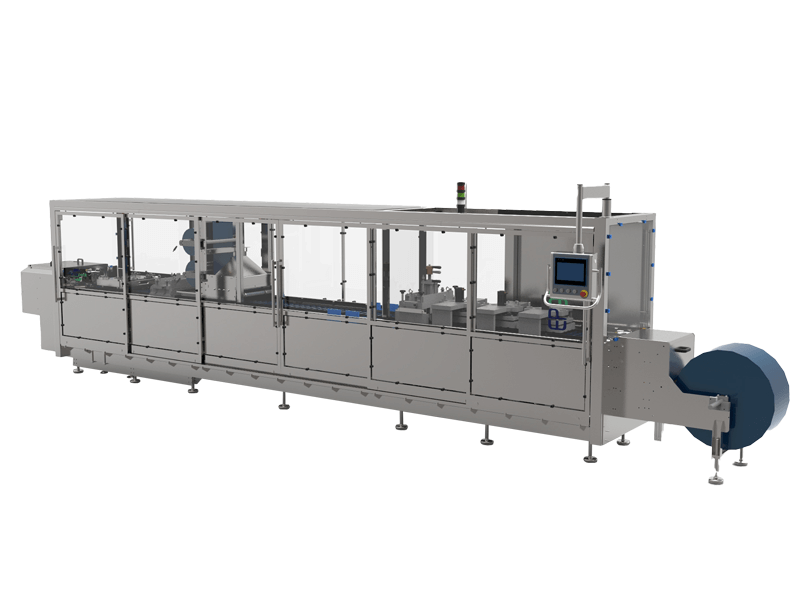

Introducing the EP9000

A versatile and high-performance HFFS machine designed for DIP pot packaging.

With speeds reaching up to 25 cycles per minute, it combines efficiency with customization.

Equipped with advanced options like jumbo film roll alimentation, MAP processing, and vision control, the EP9000 ensures optimal performance and product quality.

Watch the video to discover how this cutting-edge machine can streamline your production.